About Corian Inlaid Graphics

1. Computer Cut

|

2. Inlaid Graphics

|

What’s the Cost?

Our signs are the least expensive signs you will ever buy because they will be the last signs you will buy. You will NEVER replace these signs due to:

|

|

|

Inlaid Signs

Permanent-signs.com pioneered the use of Corian ® solid surface material for interior and exterior signage. The same properties that make Corian valuable in residential and commercial construction make it an excellent substrate for signage. Our proprietary process of inlaying the graphic elements creates visually stunning, infinitely flexible and virtually indestructible signs.

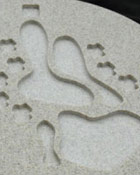

Using sophisticated computerized equipment, we have developed a process for cutting deep into the DuPont Corian substrate. After we have cut the image, we use our proprietary techniques and resins to inlay the required graphics. Our inlay process is what makes our signs so durable. The materials that make the graphic images become an integral part of the DuPont Corian substrate. No painting. No repair. No worries for you!

The Corian polymers and multi-part resins are naturally impervious to moisture, thermally stable, and UV resistant. No secondary layers or surface coatings are required to protect your message. Our signs are easy to clean and resistant to vandals and fingerprints, graffiti and other substances can be easily wiped away. Permanent-signs.com won’t crack, chip, tear or peel. Graphics will remain bright and details clear.

We only use the highest quality solid surface material to create our signs. Corian is available in dozens of different colors. Graphic elements can be rendered in dozens of colors, based on the Pantone color system.

About Corian®

Corian is the brand name for a solid surface material created by DuPont in 1967. It is composed of acrylic polymer and alumina trihydrate. Corian’s physical properties allow it to be joined, shaped, and finished into a wide variety of products. Cross-section cuts show consistent color and particulate patterning evenly distributed throughout the material. Nicks and scratches can be buffed out with a Scotch-Brite pad or orbital sander. In the fabrication process, joints can be made invisible by joining the relevant pieces with Corian’s own color-matched two-part acrylic epoxy. The pieces are clamped tightly together in order to express any excess adhesive. After the adhesive cures, the junction area is sanded and polished to create a virtually invisible joint. Corian can also be thermoformed by heating it to 300°F (150°C), allowing unique shapes to be created.

Virtually Maintenance Free

Permanent-signs.com is virtually impervious to the chief environmental factors that cause other types of signs to deteriorate. The inevitable accumulations of airborne particulates, road salt, bird droppings or markings placed by vandals can be easily removed with mild solvents and/or buffing with a fine abrasive pad. Due to our unique process and materials, the original color and detail in the sign can never be worn away.

We begin by cutting deep into DuPont Corian, driven by sophisticated computer-operated equipment.

We begin by cutting deep into DuPont Corian, driven by sophisticated computer-operated equipment. Next we inlay additional Corian of different colors and styles, and finally polish to a smooth finish, engineered to look great for many years.

Next we inlay additional Corian of different colors and styles, and finally polish to a smooth finish, engineered to look great for many years.